Steam-injection vacuum pump

Product description

Steaming-injection vacuum pump forms vacuum in the suction chamber in a way of that a pressured steam passing through Laval nozzle becomes faster and in lower pressure and then enters into the suction chamber to mix with medium, carries the medium moving to the expansion tube with lower speed and higher pressure, and finally into next injector or the atmosphere. Due to the client needs different vacuum degree, each steam-injection vacuum pump can be series-connected with single or multiple-grade injectors. The more the stages of injectors are adopted, the higher the vacuum degree will be obtained (the lower the residual pressure). The relationship of Suction pressure with stages is shown as the follows:

|

Grade |

1 |

2 |

3 |

4 |

|

Suction pressure Kpa£©KPa |

¡Ý14 |

5.3-8 |

0.67-1.33 |

0.133-0.67 | In order to reduce the working load and steam consumption of the first grade and second grade injectors, an intermediate condenser is placed between the first grade and second grade injector.

In order to reduce the emptying noises of the first grade injector, a muffling condenser is placed after the first grade injector.

The intermediate condenser and muffling condenser consists of three types: spraying direct-cooling type, hybrid direct-cooling type and tube indirect cooling type.

Type denotations Applications

1P series: suitable to gas transfer, tail gas recovery; evaporation by pressure relief, hydrogen addition decomposition; catalytic reforming.

2P series: suitable to chemical fiber and grease dehydration vacuum evaporation of

non-organic salt, base liquor and other compounds.

3P series: suitable to glycerol, grease distillation, grease decolorization, slice drying, vacuum deaeration, monomer recovery, concentrated crystallization, vacuum bleaching and vacuum resurgence.

4P series: suitable to fatty acid distillation, grease deodorization, concentrated crystallization, sublimation drying and vacuum vegetable dehydration.

1P series grade-1 steam-injection vacuum pump

Technical parameters

|

Item \Type |

Bleeding quantity kg/hr |

Suction pressure KPa |

Working steam consumptio kg/hr |

Working steam pressure MPa |

Cooling water |

Net equipment weigh kg |

|

Temp¡æ |

Circulation quantitym3/hr |

|

1P15-14/0.6 -L(H) |

15 |

14 |

185 |

0.6 |

¡Ü45 |

5.5 |

154 |

|

1P40-14/0.6 -L(H) |

40 |

14 |

500 |

0.6 |

¡Ü45 |

15 |

208 |

|

1P80-14/0.6 -L(H) |

80 |

14 |

1000 |

0.6 |

¡Ü45 |

30 |

440 |

|

1P150-14/0.6 -L(H) |

150 |

14 |

1150 |

0.6 |

¡Ü45 |

34.5 |

440 |

|

1P600-14/0.6 -L(H) |

600 |

14 |

4000 |

0.6 |

¡Ü45 |

120 |

2024 |

|

1P1500-14/0.6 -L(H) |

1500 |

14 |

10000 |

0.6 |

¡Ü45 |

300 |

5000 |

|

1P5000-14/0.6 -L(H) |

5000 |

14 |

33400 |

0.6 |

¡Ü45 |

1000 |

15000 |

|

1P10000-14/0.6 -L(H) |

10000 |

14 |

66600 |

0.6 |

¡Ü45 |

2000 |

22000 | Notes

1. The permissive minimum steam working pressure is 0.3Mpa (absolute pressure). The customer should make it clear so that our com pany can provide proper nozzle according to required steam working pressure;

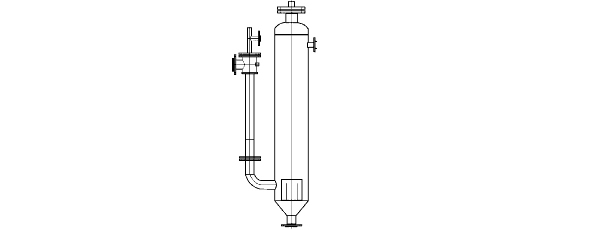

2. The sketch on the right shows a hybrid direct-cooling condenser, our company can provide tube still indirect-cooling condenser;

3.This pump can also work without muffling condenser. This pump with muffling condenser can reduce working noises. Application Cases Application Cases

1.Used for concentrated evaporation of compounds

2.Used for vacuum concentration of non-organic salts and base liquor;

3. Used for grease precipitation and dehydration;

4. Used for processing of phthalic anhydride..2P series grade-2 steam-injection vacuum pump

Technical parameters:

|

Item

Type |

Bleeding quantitykg/hr |

Suction pressureKPa |

Working steam consumptiokg/hr |

Working steam pressure MPa |

Cooling water |

Net equipment weigh kg |

|

Noncondensing gas |

Concretionary gas |

Temp¡æ |

Circulation quantitym3/hr |

|

2P(10+25)-5.3/0.6-L(H) |

10 |

25 |

5.3 |

190 |

0.6 |

¡Ü40 |

11 |

260 |

|

2P(10+40)-5.3/0.6-L(H) |

10 |

40 |

5.3 |

200 |

0.6 |

¡Ü40 |

13 |

270 |

|

2P(13+27)-5.3/0.6-L(H) |

13 |

27 |

5.3 |

200 |

0.6 |

¡Ü40 |

13 |

270 |

|

2P(25+10)-5.3/0.6-L(H) |

25 |

10 |

5.3 |

266 |

0.6 |

¡Ü40 |

16 |

280 |

|

2P(20+60)-5.3/0.6-L(H) |

20 |

60 |

5.3 |

331 |

0.6 |

¡Ü40 |

20 |

250 |

|

2P(15+35)-5.3/0.6-L(H) |

15 |

35 |

5.3 |

241 |

0.6 |

¡Ü40 |

14 |

290 |

|

2P(20+20)-5.3/0.6-L(H) |

20 |

20 |

5.3 |

236 |

0.6 |

¡Ü40 |

14 |

270 |

|

2P(20+40)-5.3/0.6-L(H) |

20 |

40 |

5.3 |

241 |

0.6 |

¡Ü40 |

14 |

290 |

|

2P(50+180)-5.3/0.6-L(H) |

50 |

180 |

5.3 |

760 |

0.6 |

¡Ü40 |

45 |

510 |

|

2P(80+180)-5.3/0.6-L(H) |

80 |

180 |

5.3 |

1100 |

0.6 |

¡Ü40 |

65 |

600 |

|

2P(160+150)-5.3/0.6-L(H) |

160 |

150 |

5.3 |

1400 |

0.6 |

¡Ü40 |

80 |

600 | Notes:

1. The permissive minimum steam working pressure is 0.3Mpa (A). The customer should make it clear so that our company can provide proper nozzle according to required steam working pressure;

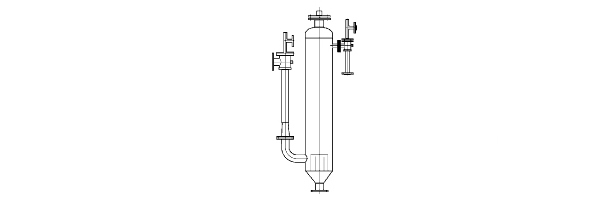

2. The sketch on the right shows a hybrid direct-cooling condenser, our company can provide tube still indirect-cooling condenser;

3. L+11M refers to the elevation deviation between water (tank) 3 level and the support

Application Cases Application Cases

1. Used for concentrated evaporation of compounds;

2. Used for vacuum concentration of non-organic salts and base liquor;

3. Used for grease precipitation and dehydration;

4. Used for processing of phthalic anhydride.

3P series grade-3 steam-injection vacuum pump

Technical parameters:

|

Item

Type |

Bleeding quantitykg/hr |

Suction pressure Kpa |

Working steam consumptiokg/hr |

Working steam pressure Mpa |

Cooling water |

Net equipment weigh kg |

|

Noncondensing gas |

Concretionary gas |

Temp¡æ |

Circulation quantitym3/hr |

|

3P£¨5+25£©-1.07/0.6-L(H) |

5 |

25 |

1.07 |

172 |

0.6 |

¡Ü35 |

13 |

300 |

|

3P£¨10+35£©-1.07/0.6-L(H) |

10 |

35 |

1.07 |

238 |

0.6 |

¡Ü35 |

20 |

340 |

|

3P£¨10+40£©-1.07/0.6-L(H) |

10 |

40 |

1.07 |

345 |

0.6 |

¡Ü35 |

40 |

650 |

|

3P£¨15+25£©-1.07/0.6-L(H) |

15 |

25 |

1.07 |

386 |

0.6 |

¡Ü35 |

45 |

650 |

|

3P£¨15+40£©-1.07/0.6-L(H) |

15 |

40 |

1.07 |

430 |

0.6 |

¡Ü35 |

50 |

680 |

|

3P£¨15+50£©-1.07/0.6-L(H) |

15 |

50 |

1.07 |

470 |

0.6 |

¡Ü35 |

55 |

680 |

|

3P£¨15+80£©-1.07/0.6-L(H) |

15 |

80 |

1.07 |

530 |

0.6 |

¡Ü35 |

64 |

700 |

|

3P£¨25+90£©-1.07/0.6-L(H) |

25 |

90 |

1.07 |

650 |

0.6 |

¡Ü35 |

78 |

750 |

|

3P£¨30+70£©-1.07/0.6-L(H) |

30 |

70 |

1.07 |

680 |

0.6 |

¡Ü35 |

80 |

680 |

|

3P£¨30+100£©-1.07/0.6-L(H) |

30 |

100 |

1.07 |

800 |

0.6 |

¡Ü35 |

95 |

1250 |

|

3P£¨50+80£©-1.07/0.6-L(H) |

50 |

80 |

1.07 |

830 |

0.6 |

¡Ü35 |

100 |

1250 |

|

3P£¨30+200£©-2.0/0.6-L(H) |

30 |

200 |

2 |

820 |

0.6 |

¡Ü35 |

100 |

1250 |

|

3P£¨20+320£©-2.67/0.6-L(H) |

20 |

320 |

2.67 |

840 |

0.6 |

¡Ü35 |

100 |

2650 | Notes:

1. The permissive minimum steam working pressure is 0.3Mpa (absolute pressure). The customer should make it clear so that our company can provide proper nozzle according to required steam working pressure;

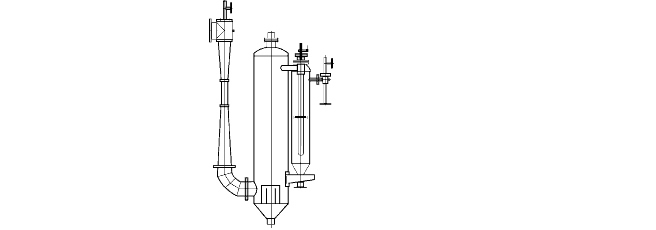

2.The sketch on the right shows a hybrid direct-cooling condenser, our company can provide tube still indirect-cooling condenser;

3. L+11M refers to the elevation deviation between water (tank) 3 level and the support. Application Cases Application Cases

1. Used for vacuum deaeration of viscose rayon;

2. Used for vegetable grease decorization and deodorization;

3. Used for vacuum bleaching;

4. Used for spray cooling;

5. Used for chemical slice drying;

6. Used for chemical monomer recovery;

7. Used for vacuum resurgence of tobacco;

8. Used for glycerol distillation;

9. Used for concentrated crystallization

4P series grade-4 steam-injection vacuum pump

Technical parameters

|

Item

Type |

Bleeding quantitykg/hr |

Suction pressure Kpa |

Working steam consumptiokg/hr |

Working steam pressure Mpa |

Cooling water |

Net equipment weigh kg |

|

Noncondensing gas |

Concretionary gas |

Temp¡æ |

Circulation quantity m3/hr |

|

4P 5-0.13/0.6-L(H) |

5 |

|

0.133 |

161 |

0.6 |

¡Ü35 |

20 |

350 |

|

4P£¨5+5£©-0.133/0.6-L(H) |

5 |

5 |

0.133 |

267 |

0.6 |

¡Ü35 |

31 |

750 |

|

4P£¨5+25£©-0.67/0.6-L(H) |

5 |

25 |

0.67 |

340 |

0.6 |

¡Ü35 |

40 |

1100 |

|

4P£¨10+35£©-0.4/0.6-L (H) |

10 |

35 |

0.4 |

450 |

0.6 |

¡Ü35 |

55 |

1300 |

|

4P£¨10+40£©-0.123/0.6-L(H) |

10 |

40 |

0.133 |

680 |

0.6 |

¡Ü35 |

81 |

1700 |

|

4P£¨10+50£©-0.26/0.6-L(H) |

10 |

50 |

0.26 |

660 |

0.6 |

¡Ü35 |

80 |

1600 |

|

4P£¨10+60£©-0.4/0.6-L(H) |

10 |

|

0.4 |

680 |

0.6 |

¡Ü35 |

80 |

1600 |

|

4P£¨20+50£©-0.4/0.6-L(H) |

20 |

|

0.4 |

760 |

0.6 |

¡Ü35 |

91 |

1600 |

|

4P15-0.133/0.6-L(H) |

15 |

|

0.133 |

400 |

0.6 |

¡Ü35 |

48 |

1300 |

|

4P20-0.133/0.6-L(H) |

20 |

|

0.133 |

530 |

0.6 |

¡Ü35 |

64 |

1300 |

|

4P30-0.67/0.6-L(H) |

30 |

60 |

0.67 |

590 |

0.6 |

¡Ü35 |

71 |

1100 |

|

4P50-0.4/0.6-L(H) |

50 |

50 |

0.4 |

750 |

0.6 |

¡Ü35 |

90 |

1300 |

|

4P£¨30+130£©-0.4/0.6-L(H) |

30 |

130 |

0.4 |

1460 |

0.6 |

¡Ü35 |

175 |

3200 |

|

4P£¨10+80£©-0.4/0.6-L(H) |

10 |

80 |

0.4 |

680 |

0.6 |

¡Ü35 |

81 |

1700 |

|

4P£¨30+150£©-0.26/0.6-L(H) |

30 |

150 |

0.26 |

2150 |

0.6 |

¡Ü35 |

260 |

4100 |

|

4P£¨15+15£©-0.67/0.6-L(H) |

15 |

15 |

0.67 |

460 |

0.6 |

¡Ü35 |

55 |

667 |

|

4P£¨30+300£©-0.4/0.6-L(H) |

30 |

300 |

0.4 |

2840 |

0.6 |

¡Ü35 |

340 |

4800 |

|

4P25-0.133/0.6-L |

25 |

|

0.133 |

670 |

0.6 |

¡Ü35 |

80 |

1300 |

|

4P£¨40+20£©-0.133/0.6-L(H) |

40 |

20 |

0.133 |

1370 |

0.6 |

¡Ü35 |

140 |

5000 |

|

4P£¨50+30£©-0.133/0.6-L(H) |

50 |

30 |

0.133 |

1905 |

0.6 |

¡Ü35 |

200 |

7135 | Notes

1. The permissive minimum steam working pressure is 0.3Mpa (absolute, pressure). The customer should make it clear so that our company can provide proper nozzle according to required steam working pressure;

2. The sketch on the right shows a hybrid direct-cooling condenser, our company can provide tube still indirect-cooling condenser.

Application Cases

1. Used for fatty acid distillation,

2. Used for chemical monomer recovery;

3. Used for essence and perfume distillation

4. Used for vegetable grease deodorization;

5. Used for chemical slice drying;

|

|