Filter cartridge series

Product description

Nantong Sanlian Petrochemical Equipment Manufacture Co. LTD has produced serial cartridge products (filter elements), successfully initiated the FNI fiber sintered filter cartridge in China to replace correspondent foreign products. The FM metal filter cartridges, FP non-metal filter cartridges and FP ceramic filter cartridges and filter bags produced by our company are well evaluated by the customers.

Classifications of filter cartridge

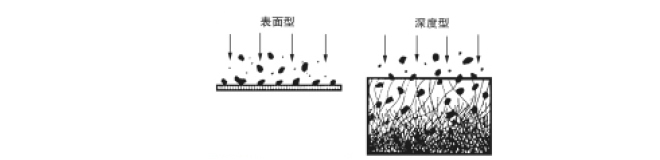

¡ª¡ªSurface filtering: Fully depends on the capturing of particles on the filter cartridge surface, the filtering holes on the cartridge surface are uniform from top to bottom.

¡ª¡ªDeep filtering: capture the particles in the deep layer of the cartridge rather than surface filtering. The filter cartridge surface is composed of fiber sintered material or resin sintered material.

Difference between surface filtering and deep filtering

¡ª¡ªThe deep filtering cartridge is a kind of one-time utilization device while surface filtering cartridge can be reused after washing.

Difference between surface filtering and deep filtering

¡ª¡ªThe deep filtering cartridge is a kind of one-time utilization device while surface filtering cartridge can be reused after washing.

¡ª¡ªSurface filtering approximates absolute filtering while deep filtering has nominal accuracy.

-¡ª¡ªThe captured particle quantity of deep filtering is generally more than that of surface filtering so that the cartridge can be used for longer time.

¡ª¡ªSurface filtering doesn¡¯t suit to soft and fiber particles while deep filtering suits to filtration of all soft and fiber particles.

¡ª¡ªDifference of pressure loss and flow rate between surface filtering and deep filtering is very big.

Type of cartridge |

Process quantity |

Accuracy stability |

Pressure difference variation |

Dust quantity |

Heat

-resistance |

Acid & base resistance |

Anti

-dissolvent |

Material drop |

Strength |

Wash-

regeneration |

Stainless steel fiber sintered cartridge |

¡ñ |

¡ñ |

¡ñ |

¡ñ |

¡ñ |

¡÷ |

¡ñ |

¡ñ |

¡ñ |

¡ñ |

Multiple-layer stainless steel fiber sintered cartridge |

¡ñ |

¡ñ |

¡ñ |

¡÷ |

¡ñ |

¡÷ |

¡ñ |

¡ñ |

¡ñ |

¡ñ |

Metal powder sintered cartridge |

¡÷ |

¡ñ |

¡ñ |

¡÷ |

¡ñ |

¡ñ |

¡ñ |

¡÷ |

¡÷ |

¡ñ |

Fiber sintered cartridge |

¡ñ |

¡ñ |

¡ñ |

¡ñ |

¡÷ |

¡ñ |

¡ñ |

¡ñ |

¡ñ |

¡Á

|

Wire winded cartridge |

¡ñ |

¡÷ |

¡ñ |

¡ñ |

¡÷ |

¡ñ |

¡÷ |

¡ñ |

¡ñ |

¡Á

|

Folding ¨Ctype polypropylene cartridge |

¡ñ |

¡ñ |

¡÷ |

¡÷ |

¡÷ |

¡ñ |

¡÷ |

¡ñ |

¡÷ |

¡Á

|

Ceramic cartridge |

¡÷ |

¡ñ |

¡÷ |

¡÷ |

¡ñ |

¡ñ |

¡ñ |

¡÷ |

¡÷ |

¡ñ |

Notes:¡ñ-- Good performance£»¡÷-- Ordinary performance£»¡Á-- bad performance

FM metal filter cartridge

1¡¢FM-¢ñstainless steel and fiber-sintered cartridge ¡ö Product features

stainless steel and fiber sintered cartridge adopts stainless steel fiber sintered material, features high filtration, low resistance, big flow rate, high dust capturing capability and long lifetime, acid & base resistance; anti-dissolvent, regeneration use.

¡ö Product applications

¡ª¡ª Petrochemical industry: for oil, dissolvent, gas and natural gas filtration

¡ö Product features

stainless steel and fiber sintered cartridge adopts stainless steel fiber sintered material, features high filtration, low resistance, big flow rate, high dust capturing capability and long lifetime, acid & base resistance; anti-dissolvent, regeneration use.

¡ö Product applications

¡ª¡ª Petrochemical industry: for oil, dissolvent, gas and natural gas filtration

¡ª¡ªChemical fiber industry: high polymer material filtration

¡ª¡ªPharmaceutical and electronic industries: asepsis gas and water filtration

¡ö Main performance parameters

|

Absolute filtering accuracy ¦Ìm |

Thickness mm |

Porosity % |

Impurity acceptance mg/cm2 |

Mean permeability L/dm2min |

|

3 |

0.35 |

65 |

6.40 |

9 |

|

5 |

0.34 |

78 |

5.47 |

34 |

|

7 |

0.27 |

72 |

6.47 |

57 |

|

10 |

0.32 |

77 |

7.56 |

100 |

|

15 |

0.37 |

80 |

7.92 |

175 |

|

20 |

0.49 |

81 |

12.44 |

255 |

|

25 |

0.61 |

79 |

19.38 |

320 |

|

30 |

0.63 |

79 |

23.07 |

455 |

|

40 |

0.66 |

77 |

25.96 |

580 |

|

60 |

0.70 |

87 |

33.97 |

1000 |

Notes:

(1) Test for impurity acceptance accords with ISO4572 standard, the final pressure loss of the filter felt is 8 times of initial loss

(2) Test for mean permeability with air pressure is 200Pa accords with ISO4572 standard,

(3) Material for filter felt is 316L.

¡ö Main dimensions

|

Type |

D |

L |

M |

Filtering areas m2 |

Filtering accuracy µm |

|

FM-I-15 |

§æ35 |

424 |

M20¡Á1.5 |

0.15 |

0.3~60 |

|

FM-I-26 |

§æ50 |

410 |

M33¡Á1.5 |

0.26 |

|

FM-I-50 |

§æ60 |

527 |

M48¡Á£² |

0.50 |

Note: Special dimensions are to be provided on customer¡¯s request.

2¡¢FM-II multi-layer stainless sintered filter element

¡ö Product features

Adopt imported five-layer stainless sintered filtering material with characteristics of:

¡ö Product features

Adopt imported five-layer stainless sintered filtering material with characteristics of:

¡ª¡ª The shape of the screen holes is stable, uniform pore size, high filtering accuracy.

¡ª¡ª Good fluid penetration, flowing capability and little resistance

¡ª¡ªSmooth pore canal, easy wash for regeneration.

¡ª¡ª High strength and rigidity, wide material range, high temperature and erosion resistance.

¡ö Applications:

FM-II type multi-layer stainless sintered filter element can be used for gas purification, sewage filtration, catalytic agent separation, hydraulic oil and fuel oil filtration, finer medicine and food, beverage filtration and filtration for products such as colorant, printing ink, ceresin wax and sulphur.

¡ö Main performance parameters

| Filtration accuracy µm |

5 |

10 |

20 |

40 |

75 |

100 |

| Air penetration L/min.cm2.Pa |

3.5x10-4 |

7.2x10-4 |

3x10-3 |

7.5x10-3 |

3x10-2 |

¡Ý5x10-2 |

| Material |

304¡¢316L¡¢1Cr18Ni9Ti¡¢GH30¡¢GH40 High temperature alloy |

| Temperature¡æ |

Stainless stee£º¡Ü500£»High temperature alloy£º¡Ü900 |

¡ö Main dimensions

|

D |

§æ35 |

§æ35 |

§æ35 |

|

M |

M20X1.5 |

M33X1.5 |

M48X2 |

|

L |

150~1000 |

|

H |

18 |

20 |

20 |

Note: Special dimensions are to be provided on customer¡¯s request.

3¡¢FM-III metal powder sintered filter element

¡ö Product features:

The filter element is made of metal powder sintered small pore material with features of high-temperature and erosion resistance, uniform pore (hole) distribution, good permeability, high mechanical strength, easy wash for regeneration and easy for welding and mechanical processing.

¡ö Applications

¡ª¡ªFM-III type metal powder sintered filter element can be used in the fields of chemical, petroleum, metallurgical engineering, environment protection, fermentation for gas and liquor filtration and separation, such as:

¡ö Product features:

The filter element is made of metal powder sintered small pore material with features of high-temperature and erosion resistance, uniform pore (hole) distribution, good permeability, high mechanical strength, easy wash for regeneration and easy for welding and mechanical processing.

¡ö Applications

¡ª¡ªFM-III type metal powder sintered filter element can be used in the fields of chemical, petroleum, metallurgical engineering, environment protection, fermentation for gas and liquor filtration and separation, such as:

¡ª¡ªCoarse and fine filtration of medical liquor, oil, beverage, mineral water;

¡ª¡ªPurification of various gas, steaming vapor, degerming and oil smoke removal.

¡ö Main performance parameters

|

Filtration accuracy¦Ìm |

Porosity % |

Penetrating coefficient m2 |

Thickness mm |

Material |

|

2~4 |

30~40 |

>0.5X10-13 |

1~3 |

306.316L Titanium material, nickel, Monel 8-3 bronze or tin-10 |

|

4~10 |

30~40 |

>1.4X10-13 |

1~3 |

|

10~14 |

30~40 |

>0.4X10-12 |

1~3 |

|

14~20 |

30~40 |

>1.8X10-12 |

1~3 |

|

20~30 |

30~40 |

>4.6X10-12 |

1~3 |

|

30~40 |

30~40 |

>0.9X10-11 |

1~3 |

|

40~60 |

15~40 |

>55X10-12 |

3~5 |

|

60~80 |

15~40 |

>85X10-12 |

3~5 |

|

80~100 |

15~40 |

>12X10-12 |

3~5 |

¡ö Main dimensions

|

D |

30 |

40 |

50 |

60 |

70 |

|

M |

M20X1.5 |

M20X1.5 |

M33X1.5 |

M48X2 |

M48X2 |

|

L |

100 |

200 |

200 |

300 |

500 |

|

200 |

300 |

300 |

400 |

600 |

|

- |

400 |

400 |

500 |

700 |

|

- |

- |

500 |

600 |

800 |

|

- |

- |

800 |

800 |

1000 | Note: Special dimensions are to be provided on customer¡¯s request.

|

|