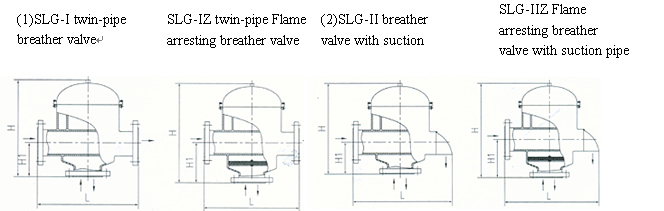

Breather valve, Flame arresting breather valve

Description of products

According to national standard¡¶Fire-prevention code of petrochemical enterprise design¡·( GB50160-92 ) that the vat for containing Cat.A and B liquids must have flame arrestor and breathing valve. It is very clear that breather valve and flame arrestor is an indispensable device for container. It can keep the storage pressure balanced to prevent the container from being damaged during over-pressure or vacuum condition and reduce the loss and volatilization of medium in the container.

Breather valves manufactured by our company feature compact structure, large flow rate, high-quality sealing performance and less leakage. Our company has developed an advanced world-level breather valve with arrester on the inlet of the breather valve, which can prevent any fire source into the valve body and features small compact, lightweight and convenient repair, cleaning and replacement.

Main technical specifications

¡ôSuitable to special liquid and gas of petroleum, chemical, medicinal energy engineering;

¡ô Operating pressure:

A£º -295Pa (-30mmH2O) +355Pa (+36mmH2O)

B£º -295Pa (-30mmH2O) +980Pa (+100mmH2O)

C£º -295Pa (-30mmH2O) +1750Pa (+180mmH2O)

D£º -295Pa (-30mmH2O) +98000Pa (+10000mmH2O)

¡ôExplosion class; BS 5501£ºIIA¡¢IIB¡¢IIC

¡ôShell material: Carbon steel Al. alloy,

¡ôMaterial of valve disc and seat: Al.alloy, stainless steel;

¡ôSealing material: Tetrafluoroethylene;

¡ôFlange standards: HG20592-97 PN1.0. If the customer requires GB,HGJ, JB, ANSI,JIS or change pressure grade, clear it in the contract.

¡ôManufacturing, test and inspection should be in accordance with standards: SY7511, ¡¶Manufacturing, test and inspection of breather valve used for petroleum container ¡·, GB5908-1986 ¡¶Fire arrestment performance and test methods of arrestor used for petroleum container¡·.

Product model and specifications

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

280

350 |

430

500 |

430

600 |

530

600 |

630

700 |

730

820 |

|

H1 |

110

180 |

182

250 |

180

250 |

220

290 |

260

330 |

320

400 |

|

L |

320 |

450 |

450 |

320 |

750 |

850 | Figures in the bottom line refer to SLG-IZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

280 |

430 |

430 |

530 |

630 |

730 |

|

350 |

500 |

500 |

600 |

700 |

820 |

|

L |

210 |

350 |

350 |

535 |

700 |

850 | Figures in the bottom line refer to SLG-IIZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

280 |

400 |

400 |

470 |

550 |

620 |

|

320 |

470 |

470 |

540 |

625 |

700 |

|

H1 |

110 |

160 |

160 |

200 |

250 |

290 |

|

180 |

270 |

270 |

270 |

320 |

370 |

|

L |

320 |

420 |

420 |

520 |

650 |

760 |

|

L1 |

185 |

250 |

250 |

320 |

400 |

480 | Figures in the bottom line refer to SLG-IIIZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

280 |

430 |

530 |

530 |

630 |

730 |

|

350 |

500 |

600 |

600 |

700 |

820 |

|

H1 |

110 |

180 |

180 |

200 |

260 |

320 |

|

180 |

250 |

250 |

290 |

330 |

400 |

|

L |

310 |

450 |

450 |

635 |

800 |

950 | Figures in the bottom line refer to SLG-IVZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

250 |

400 |

400 |

470 |

550 |

625 |

|

320 |

470 |

470 |

540 |

620 |

700 |

|

L |

290 |

420 |

420 |

535 |

700 |

635 | Figures in the bottom line refer to SLG-VZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

250 |

400 |

400 |

470 |

550 |

620 |

|

320 |

470 |

470 |

540 |

625 |

700 |

|

H1 |

110 |

160 |

160 |

200 |

250 |

290 |

|

180 |

230 |

270 |

270 |

320 |

370 |

|

L |

300 |

420 |

420 |

520 |

650 |

760 |

|

L1 |

185 |

250 |

250 |

320 |

400 |

480 | Figures in the bottom line refer to SLG-VIZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

270 |

400 |

400 |

470 |

550 |

620 |

|

340 |

470 |

470 |

540 |

620 |

700 |

|

L |

290 |

420 |

420 |

535 |

700 |

635 | Figures in the bottom line refer to SLG-VIIZ size

|

DN |

50 |

80 |

100 |

150 |

200 |

250 |

|

H |

280 |

430 |

430 |

530 |

630 |

730 |

|

350 |

500 |

500 |

600 |

700 |

820 |

|

H1 |

110 |

180 |

180 |

220 |

260 |

320 |

|

180 |

250 |

250 |

290 |

330 |

400 |

|

L |

310 |

450 |

450 |

635 |

800 |

950 | Figures in the bottom line refer to SLG-VIIIZ size

|

|