Auto washing brush filter SPFZ-Y ˇ˘ SPFZ-L-IŁ¨II)Features ˇńThe auto washing brush filter is an electrical device with full automatic and self ¨Cwashing function. It can reduce repair and maintenance fee and implements protection to the downstream equipments.

ˇńPrecise space-saving design with linear structure.

ˇńHigh-precision high strength wedge screen with filtering accuracy 100-3000¦Ěm.

ˇńSimple wash mode: stainless steel brush.

ˇńWithout fluid interruption during back washing.

ˇńLess water consumption during back washing, less than 1% of overall flow.

ˇńSuitable to the filtration of flow with big flow rate and high level pollution.

Applications ˇńWater treatment for environment protection

ˇńSteel industry

ˇńMetallurgical industry

ˇńChemical industry

ˇńPlastic industry

ˇńAgricultural irrigationWorking principle

Filtration:Fluids enter from inlet and flow out from the small chinks of the wedge screen in the filter. Dusts or particle are easy to be remained by the screen. When dusts are accumulated at the screen, pressure difference will appear in the inlet and outlet locations.Washing:If the pressure difference in the inlet and outlet reaches0.5kg/cm2, the backwashing system functions automatically by the control of differential controller on the frame body. Washing operation is carried out by sewage valve and rotary stainless steel brush. Particles are easily brushed out by the steel brush and drained out from the sewage valve. The backwashing operation lasts 15 seconds without flow failure.

Control:

When different pressure reaches preset value through the screen, the differential controller will send a signal to PLC controller. And the PLC controller will initiate motor and sewage valve to start wash. When fault happens, pressure reduction will occur. The filter will remain in a washing state and send out alarming signals. Continuous backwashing operation is controlled in 5 minutes.Technical parameters

|

Maximum flow rate |

1000m3/h |

According to the filtering precision and impurity can query to the company, my company to provide the most suitable models |

|

Minimum working pressure |

0.2Mpa(g) |

|

|

Max working pressure |

1.6Mpa(g) |

special on customer request |

|

Diameter of inlet and outlet |

DN50~DN400 |

flange standard HG20592-97 special on customer request |

|

Minimum working temperature |

80ˇć |

special on customer request |

|

Filtering accuracy |

100~3000µm |

|

|

Screen material |

provide 304,316,316Lstainless steel on requests |

|

|

Equipment material |

Provide Carbon steel or 304,316,316Lstainless steel on requests |

|

|

Motor power |

0.37~0.75KW |

|

|

Power voltage |

380V, 50Hz, 3-phase |

|

|

Backwashing flow rate |

less than 1% of overall flow |

|

|

Backwashing time |

15Ăë |

|

|

Backwashing pressure difference |

0.5kg/cm2 |

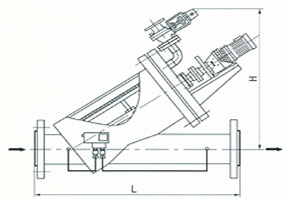

Offer design on process demand | Table for installation (SPFZ-Y)

SPFZ-Y type

|

Nominal diameter |

SizeŁ¨mmŁ© |

Sewage valve |

Reference flow rate m3/h |

|

L |

H |

|

DN50 |

600 |

400 |

DN20 |

25 |

|

DN65 |

600 |

450 |

DN20 |

30 |

|

DN80 |

700 |

500 |

DN25 |

50 |

|

DN100 |

800 |

550 |

DN25 |

80 |

|

DN125 |

900 |

600 |

DN25 |

125 |

|

DN150 |

950 |

650 |

DN25 |

150 |

|

DN200 |

1050 |

650 |

DN32 |

200 |

|

DN250 |

1250 |

750 |

DN40 |

300 |

|

DN300 |

1500 |

1020 |

DN40 |

500 |

|

DN350 |

1800 |

1240 |

DN50 |

800 |

|

DN400 |

1800 |

1310 |

DN50 |

1000 | NoteŁşFigures in the table refer to water flow rate.

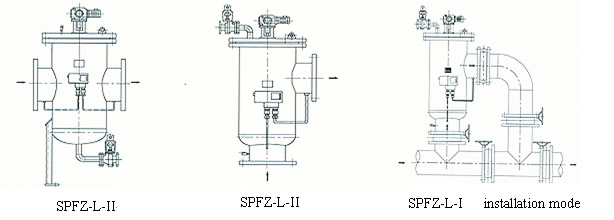

SPFZ-˘ń(˘ň) profile Notes:Because the features of material are different, the company can provide design of particular filters requested by the customers. The customer should detail related parameters such as flow rate (m3/h), filtering precision (¦Ěm), pressure (Mpa), density (kg/m3) and viscosity (CP). Please contact the company for erecting drawings. Notes:Because the features of material are different, the company can provide design of particular filters requested by the customers. The customer should detail related parameters such as flow rate (m3/h), filtering precision (¦Ěm), pressure (Mpa), density (kg/m3) and viscosity (CP). Please contact the company for erecting drawings.

|

|